Hygienic Design: reduces cleaning effort.

The new generation of LASKA machines offers the benefit of EHEDG-certified components and increased product shelf life.

Hygienic design: Reduces cleaning effort.

In the food processing industry, only one thing is more important than taste: impeccable hygiene. At LASKA we are always developing new, refined solutions so that the risk of adulteration is virtually eliminated. On our new machines, hygienic design and EHEDG-certified components ensure safety and impeccable food quality.

Here’s how we handle the risk of contamination:

We nip it in the bud.

Hygienic surfaces

LASKA only installs polished surfaces; bacteria scarcely stand a chance here. Surfaces are also chamfered so that water can run off after cleaning and the machine remains clean without any residues.

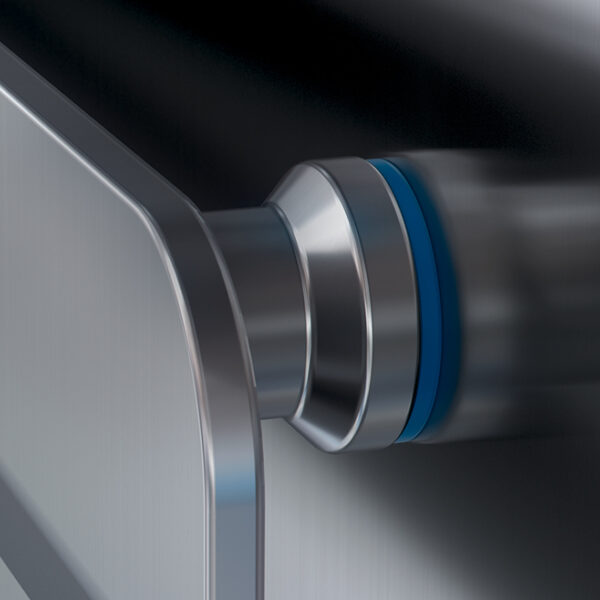

Double sealing

Wherever food is conveyed and processed, the machine room is double-sealed. Both on the drive side and the product side. The intermediate room is easy to clean using a hose.

Base feet without threads

Instead of a thread, the base feet on all new developments are now smooth in order to prevent any possible contamination.

Interior hinges

Where required, hinges will be installed on the inside in future. This means there is literally nothing to get in the way of hygienic cleaning.

Cleaning-friendly feed screw

The feed screw can be removed easily for cleaning in a few simple steps.

Conveyor belt with wipers

Smooth belts have a wiper at the end to ensure optimum hygiene during processing. The gearing is hidden hygienically in the drum to save space.

Still have questions?

If you have any questions, we are happy to answer them.